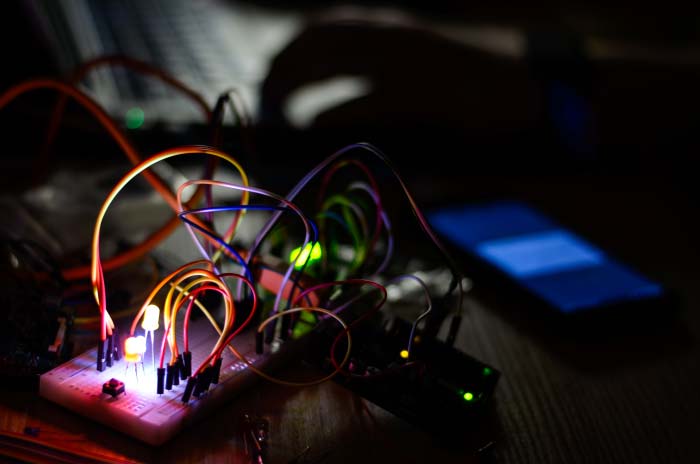

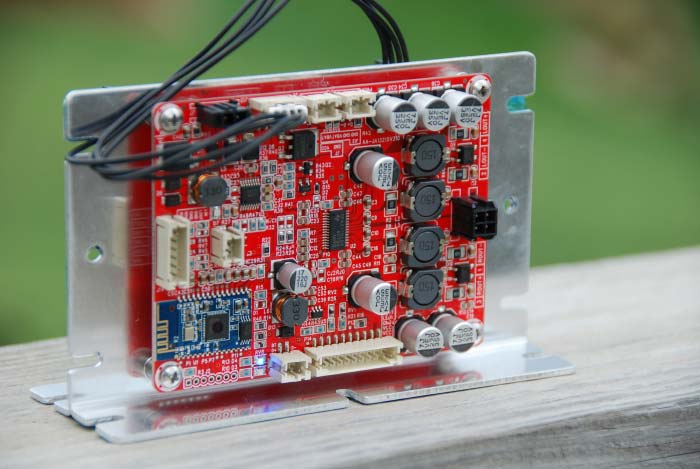

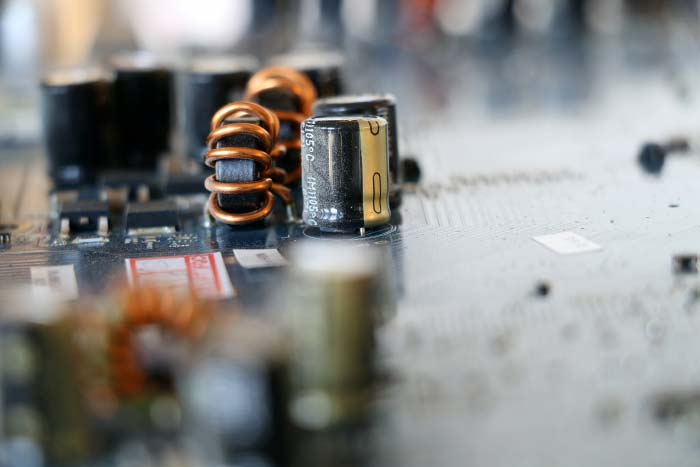

Design is a flexible and multi-phase process that involves brainstorming and planning prior to the physical creation of a prototype. Prototype design is a cost-effective way to confirm and refine your creative ideas early in the development process.

Prototype design is useful for all new products, from circuit boards to cases and 3D fabrication. We offer design services at all stages of the development cycle to ensure correct manufacture and minimize associated production costs. We specialize in PCB design prototypes and additive fabrication models for plastic enclosures and electronic products.